Circuit training

Although engine failure in modern aeroplanes is quite rare, the take-off phase incorporates all the worst aspects of this type of emergency.

The aeroplane is usually heavy, slow, low and in a nose-high attitude. These factors combine to provide the least amount of height – and therefore time – available to respond to the emergency. Successfully managing an engine failure after take-off (EFATO) is dependent entirely on efficient use of the time available.

The procedure taught in this lesson has been shown to give the best chance of survival in the case of an engine failure after take-off. Where possible and appropriate during later lessons, the student should complete the manoeuvre to the ground, for example, where there is enough runway ahead to land on. Before doing this, however, consideration must be given to the human factors discussed in this briefing and the limited time available for appropriate actions, while all the time remaining in control of the aeroplane.

As with all emergency procedure training, the emergency is simulated in such a way as to ensure there is no danger to the aeroplane or crew.

Considerable time is spent on overlearning a procedure to adopt in case it does happen. The purpose of overlearning is to produce an automatic response that best uses the time available by overcoming the initial surprise or shock (startle effect) and enhancing the decision-making process.

This briefing discusses engine failure both during and after take-off.

To adopt the recommended procedure in the event of an engine failure at low level (below 1000 feet AGL).

The modern aeroplane engine is a fairly simple, slow revving (2500 RPM versus the average car at 4500 RPM) four-stroke engine, and therefore it is very reliable. Its operation requires the mixing of air and fuel and the introduction of a spark. The result is quite predictable. Generally, the reasons aeroplane engines stop can be traced to the lack of one of the following components.

In conditions of high humidity, carburettor ice can form during taxiing and may be hard to detect at low power settings. Being aware of the temperature and moisture content of the air will alert you to the possibility of ice forming. There may be clues in the way the engine is running on the ground.

Selecting carburettor heat HOT is the first action, other than flying the aeroplane, to be taken in the event of any engine failure, and if carburettor icing is the cause of an engine failure it should re-establish smooth engine running. Selecting carburettor heat to HOT also provides an immediate alternate source of air to the carburettor, should the air filter have become blocked during take-off.

The risk of carburettor ice causing an engine failure is minimised by carrying out the preflight engine run-up. In conditions of suspected carburettor icing, after prolonged idling, it is advisable to cycle the carburettor heat just before take-off. Be aware of the ground surface when applying carburettor heat. Bypassing the filter can introduce dust and grass seeds into the carburettor, another possible cause of engine failure.

Always ensure that carburettor heat is selected to COLD before opening the throttle for take-off.

Another possible cause of the air supply being obstructed is a blockage in the carburettor air filter. In this situation, the carburettor heat, which bypasses the air filter, will provide an alternate source of air to the carburettor. The risk of filter blockage is minimised by carefully examining the air intake during the preflight inspection.

The most probable cause of engine failure is fuel contamination, ie, something in the fuel – most commonly water.

Most students are surprised to learn that mechanical failure is not the most common cause.

The risk of fuel contamination is minimised by inspecting a fuel sample during the preflight and after-refuelling checks – looking for foreign objects, colour and smell, as well as carrying out the pre-take-off engine run-up. Be aware that immediately after refuelling some water, if present, will still be in suspension, and a fuel check done too soon after refuelling may not discover this.

Be aware that if the aeroplane is not on level ground, a fuel sample check may not be capturing any water or contamination present.

Fuel starvation occurs when there is fuel on board but it's not getting to the engine.

The most common cause of fuel starvation is the pilot selecting the wrong fuel tank or placing the fuel selector in the OFF position by mistake. Other less common but possible causes are either engine-driven fuel pump failure or blocked fuel lines, injectors or fuel vents.

To help avoid fuel starvation, the student must be familiar with the aeroplane’s systems, carry out the engine run-up before take-off, and apply sound fuel planning and management procedures.

Fuel exhaustion occurs when there is no useable fuel on board, and is less likely to be a factor of EFATO than fuel starvation.

The most common cause of fuel exhaustion is poor in-flight decision making – simply running out of fuel. Another cause is leaving the fuel caps off, this allows fuel to be sucked out by the low-pressure area over the wing surface.

Fuel exhaustion is avoided by careful preflight planning, a thorough preflight inspection and being aware of how much fuel there is on board at all times. Use a fuel management procedure as outlined in the Fuel management GAP booklet.

During take-off the engine is working at its hardest and, although mechanical failure is still the least likely cause, the risk of mechanical failure is increased.

Statistically, the first reduction in power after take-off is the most common time for a mechanical failure to occur. Therefore, if a reduced power setting is to be used for the climb, full power should be maintained to a safe height, and the aeroplane cleaned up and established in the climb before power is reduced.

A thorough preflight inspection and engine run-up should be completed to check for any signs of impending mechanical failure.

Early in the take-off roll, temperatures, pressures, RPM and airspeed are quickly scanned for normal readings. If anything about the take-off roll appears abnormal – including the sound – something blocks the runway, or at ATC request, the take-off should be abandoned, also called 'aborted', by closing the throttle, braking as required, and keeping the aeroplane straight.

Remind the student of the concept of Aviate – Navigate – Communicate.

In any emergency situation the first and overriding priority of the pilot is to fly the aeroplane. Then if time permits the next two priorities can be attended to, navigate and communicate – in that order. Do not allow your students to feel that the first priority is to communicate, especially if they are trying to respond to requests from air traffic control.

Because the aeroplane is slow, low and in a nose-high attitude, an engine failure at low altitude provides little time for decision making. Therefore, the first response must be a positive and automatic movement to lower the nose to maintain best available flying speed and to close the throttle to stop any engine surges affecting the glide. The student must accept that if the engine fails at low level they are committed to a landing.

A pre-take-off safety brief will help avoid any mindset and improve decision making in the event of an emergency.

The second response turning into wind (if applicable or necessary) and choosing a suitable landing site within gliding distance. Without compromising the safe outcome of a simulation, demonstrate good decision-making by talking the student through your decision-making process. This is particularly important when deciding to select flap.

For a familiar runway, anticipated options should already be available, subject to wind, airspeed, load, and height considerations. The choice of landing sites will be limited by the height and therefore time available, but there is one sure way to improve your options – always use full runway length. Runway behind you is useless. From full length an engine failure at low altitude may present you with the perfect forced landing area – the runway ahead.

The most important consideration when selecting a suitable landing site is to avoid major obstacles – to keep the cabin intact.

Common practice is to limit the choice of landing site to no more than 45 degrees either side of the nose; a simpler and more realistic choice may be to choose anything in the windscreen.

Do not turn back to the runway. A successful turn back to the runway is beyond the capabilities of most pilots.

This is always last on your list. If time, make a MAYDAY call to alert others of your situation.

Once the student has completed the EFATO procedure, you’ll be asking them to carry out a go-around.

In this instance, the instruction to go-around means to discontinue the glide by applying full power while keeping straight with rudder, raising the nose attitude to the horizon, climbing straight ahead, retracting any flap, and continuing the climb out.

The early go-arounds should be initiated as soon as the student has carried out the immediate actions of lowering the nose and deciding where they will land. Once the student's experience increases they can be initiated at lower levels when flap decisions are committed to.

Because the time available for decision making is short, the anticipated response to an engine failure is briefed before line up.

This type of pre-take-off preparation is common in multi-engine aeroplanes and, although the choices in a single-engine aeroplane are limited, it is highly recommended. Verbally or mentally preparing a response, through visualisation before an unexpected emergency, has been shown to greatly increase the chances of success.

The take-off safety brief should include the intentions of the pilot-in-command in the event of an engine failure during the take-off roll and after take-off.

The briefing needs to consider the conditions on the day, particularly the direction of the wind in relation to the runway in use. If the wind is not directly down the runway but slightly across, then if an engine failure occurs after take-off, a gentle turn into wind would result in increased headwind and a shorter landing roll.

The type of terrain off the end of the runway should be visualised and suitable landing areas recalled from memory of earlier flights off this runway.

An example:

"Engine failure or aborted take-off before one third of the way along the runway – I will lower the nose, close the throttle and land on the remaining runway. Engine failure after one third of the way along the runway – I will lower the nose, close the throttle, select the best option and execute trouble checks and MAYDAY call if time permits."

So that there is no confusion between the simulated engine failure and an actual occurrence, advise the student that you will close the throttle and use the word "simulating". Any partial power reduction by you during the take-off is to be considered by the student as a total failure. You could use the following phrases.

"I will simulate the engine failure after take-off by closing the throttle. You are to assume that any power reduction (partial or otherwise) by me during the climb out is a total power failure simulation. During the simulations power will always be available should we need it."

Any checks that would be carried out in the event of an actual engine failure, which are not actually carried out during the simulated exercise, are known as 'touch checks'. These will be clearly identified in the briefing, and a chance available for the student to familiarise themselves before the flight. A touch check requires the student to state the check verbally and touch the appropriate control, preferably with only one finger, but not perform the required action.

At controlled aerodromes, ATC must be advised of the intention to carry out a simulated engine failure after take-off, and advised when the simulation is complete. Advise the student that you will make these calls.

At uncontrolled aerodromes, a traffic call is made to keep other traffic informed of your movements.

By varying the height at which the simulated engine failure occurs, you are increasing and decreasing the available options for the landing site and the amount of checklist items the student can complete. The student will be making decisions based on the time they have available, developing their aeronautical decision making skills (ADM).

The student should be advised that this exercise is never to be practised solo.

EFATO simulations are not to be carried out with passengers on board, nor when following traffic may conflict.

Trouble checks are a way to diagnose (or troubleshoot) the causes of an engine failure and hopefully reinstate engine operation. They cover the most common causes, and give you an increased chance of getting the engine running again.

Critically though, trouble checks are only completed when there is enough time. If there is not enough time – concentrate on flying the aeroplane, ie, first lower the nose. It’s vital that the aeroplane is consciously flown at all times, and that the pilot is not distracted by carrying out the checks, failing to fly the aeroplane.

Whenever power is reduced, the immediate action is to aviate as above, then if time permits select carburettor heat HOT, close the throttle, and carry out the trouble checks. Make sure the student gets into this habit quickly, and it becomes automatic.

F Fuel

Fuel selector ON, fuel pump ON (if applicable), change tanks (touch).

Fuel pressure and the contents gauges are checked and compared with the fuel tank selected.

M Mixture

Mixture RICH, carb heat HOT, primer LOCKED.

These are rechecked and the mixture, in the case of partial power, altered (touch) to see if there is any improvement in power or smoothness.

I Ignition

Ignition LEFT, RIGHT or BOTH (touch), check temperatures and pressures.

Trying LEFT (touch) and RIGHT (touch) magneto positions for smoother running may keep the engine running. Try to restart the engine with the ignition key (touch) if the propeller is not windmilling.

Check the temperatures and pressures for any reading outside the green range.

Further elements of the trouble checks will be introduced in following lessons.

These are completed if the aeroplane will be landing in order to minimise the risk of fire, but only if there is time available to do them.

F Fuel

Fuel OFF

Pump OFF and tank selector to OFF.

M Mixture

Mixture IDLE CUT-OFF

To stop all fuel from flowing to the engine.

I Ignition

Ignition OFF

To ensure there is no spark available to ignite any fuel.

M Master switch

Master switch OFF

After you have made the MAYDAY call and the final flap selection is made, the master switch is turned off to remove power from the aeroplane.

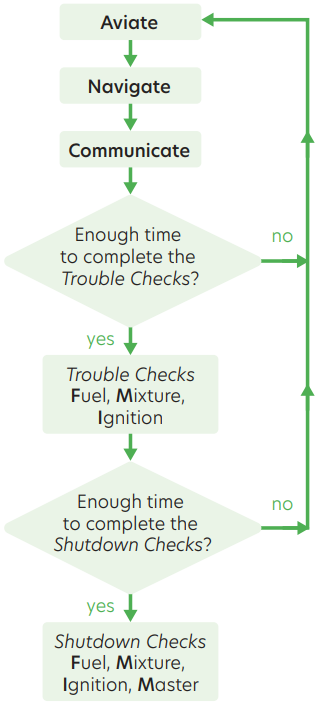

This sequence may be presented in the form of a flow chart (see Figure 1).

Figure 1 Shutdown checks

Since aeroplane systems management errors are often the root cause of in-flight emergencies, consideration must be given to systems management, regardless of how simple those systems appear. You may like to use a schematic or model to describe the fuel system, as well as providing a handout. The student should operate the fuel cocks, actually turning the fuel off and on, during the preflight inspection.

During the preflight inspection make sure loose articles are secured or removed, there is little point in making the perfect forced landing only to be hit in the head by a heavy article.

As large throttle movements will be made while operating close to the ground, those movements need to be smooth.

Encourage the student to listen to the normal sounds of the aeroplane so that they can be aware of abnormal sounds.

Avoid 'ramming' the throttle to the maximum stops when carrying out a go-around.

Checklists, mnemonics and careful preflight planning allow the student to improve their information processing capabilities.

An engine failure close to the ground can be a stressful experience for the student – even if it is simulated. For the first few engine failures give the student plenty of notice, and as their experience and competence increases, slowly remove the advanced notice.

Continued practice and overlearning the procedure will reduce their stress levels, and their responses will become automatic.

Talk through the elements of an appropriate take-off safety brief. Give the student a written version of your brief.

| Aviate | Close the throttle |

| Navigate | Keep straight and use brakes as required – backpressure is used as required to keep the aeroplane weight off the nosewheel |

| Communicate | Advise ATC (if applicable) |

Keep the cabin intact. Don't run the aeroplane nose into fence posts, steer between them.

The reason for abandoning the take-off is simulated by you and the student is talked through the actions. This may be simulated soon after full power is achieved, by advising the student, for example, that oil pressure is (simulated) zero.

Engine failure during take-off (early in the take-off roll) is simulated by partially closing the throttle.

Engine failure after take-off is simulated by closing the throttle.

| Aviate | Fly the aeroplane. Lower the nose – close the throttle and achieve best available glide speed.

Any nose-low attitude will avoid the stall. Select carburettor heat HOT (as this is a likely cause of rough running) and close the throttle, because a temporary surge in power may divert the student and cause indecision. |

| Navigate |

Follow the take-off safety brief and choose a landing site from anything in the windscreen, within easy reach and clear of major obstacles to keep the cabin intact. Use flap as required to reach the landing site. |

| Communicate | Transmit MAYDAY (touch) if time permits and when full flap has been selected, master OFF (touch).

The MAYDAY transmission from low level may have limited value at an uncontrolled aerodrome, as would the selection of 7700 on the transponder. At a controlled aerodrome, the take-off is usually monitored by ATC and only an abbreviated call should be required, for example, “MAYDAY – aeroplane registration – engine failure”. |

The priorities of the pilot-in-command should focus on landing into wind and keeping the cabin intact. However, if time permits the attitude can be adjusted for best glide, carburettor heat applied, and the trouble checks (FMI) carried out.

F Fuel

Fuel pump ON, pressure checked, change tanks (touch), contents checked.

M Mixture

Mixture RICH, primer LOCKED.

I Ignition

Ignition on LEFT or RIGHT or BOTH (touch).

If time permits, the shutdown checks can be completed to minimise fire risk.

F Fuel

Fuel OFF (touch)

M Mixture

Mixture IDLE CUT-OFF (touch)

I Ignition

Ignition OFF (touch)

M Master

Master switch OFF (touch)

Some things are beyond our control, but by paying proper attention to all preflight preparations, we can help to avoid an EFATO. Sticking to the priorities of Aviate – Navigate – Communicate greatly increases the chances of survival.

Sitting in the aeroplane, before start up, demonstrate the touch checks, and have the student complete them for themselves. They should also move the fuel selector, if they haven't had a chance to already.

At the holding point, run through your take-off safety brief, and ask them to do one next time.

Even though this briefing has concentrated on the EFATO and aborted take-off, the student is still working on the circuit and landing. Not every take-off or landing will be an opportunity to practise these actions. Pick appropriate times to carry out these exercises, taking into account student workload and traffic.

Generally you will not carry out a simulated engine failure on take-off from a touch and go, unless there is sufficient runway available, so ensure you plan when to cover each exercise carefully.

When traffic permits, start with a simulated aborted take-off. As discussed in the briefing, you will close the throttle and talk the student through the actions you want them to carry out. You may want to use a vector that is not in current use.

At the next good opportunity (having let them carry out at least one normal circuit and landing), simulate the engine failure during take-off. Early in the take-off roll, from a full length take-off, partially close the throttle and talk them though the actions you want them to carry out.

At a suitable time, when traffic permits, simulate the engine failure after take-off, don't forget to say "simulating." The first simulation should be carried out from a generous height so the student has time to take the actions required.

It cannot be stressed enough that you must keep in mind the objective and the safety of the aeroplane while providing the student with the opportunity to practise command decision making. Once the aeroplane nose has been lowered; a decision made as to the landing site; an attempt made to position for a landing; and flap selected or considered; the objective has been achieved, and the instruction to "go around" should be given. Only after these basic actions have become automatic, and where height and time permits, should any attempt to complete checks be encouraged.

As competence is achieved and circumstances permit, EFATO to a landing provides the complete experience and gives the student a true appreciation of the limited time available and the need to prioritise the actions.

Carry out the debrief.

Ask the student to learn their trouble checks and shutdown checks, and to have thought about a take-off safety briefing before the next lesson.

Engine failure after take-off whiteboard layout [PDF 45 KB]

Revised 2023